The Isuzu FTR garbage compactor truck is modified with Isuzu Category II chassis.The truck has good chassis performance, strong power, curved upper body design, advanced and beautiful appearance, reasonable structure, complete configuration, new CAN bus control system, electrical integration design, automated operation, and high work efficiency, easy to operate and maintain, optional rear bucket flip mechanism or garbage bucket flip mechanism, especially suitable for garbage collection, compression and transfer in urban and rural areas.

Algeria Isuzu FTR garbage compactor truck also called Isuzu rear loader compactor,Isuzu waste compactor truck, Isuzu garbage compactor truck, Isuzu trash compactor, Isuzu refuse collection truck, Isuzu compactor garbage truck, Isuzu rubbish truck, Isuzu waste collection vehicle. The Algeria Isuzu FTR garbage compactor truck is modified with Isuzu Category II chassis. The vehicle is mainly used for the collection and transport of a one-time non-recyclable municipal solid waste, commercial waste. It's with the features of high system pressure, large compression force, high volume rate and large loading capacity, which could make loading capacity increase 5-7 times.With the function of high automatic degrees, quick loading speed, convenient, safe and reliable operation, and preventing re-pollution.

I. Description of Algeria Isuzu FTR Garbage Compactor Truck

Key Features:

---- ISUZU chassis, perfect performance.

---- ISUZU FTR engine, super powerful; reliable performance, no overhaul within 100,000 km.

---- Compression body capacity from 3 to 20 Cublic Meter.

---- Easy operation and easy maintenance.

---- Various types of refuse container lifter are available.

II. Specification of Algeria Isuzu FTR Garbage Compactor Truck

ISUZU FTR 14cbm garbage compactor truck | |||

Vehicle Model | PT5160ZYSQ | Vehicle Brand | POWERSTAR |

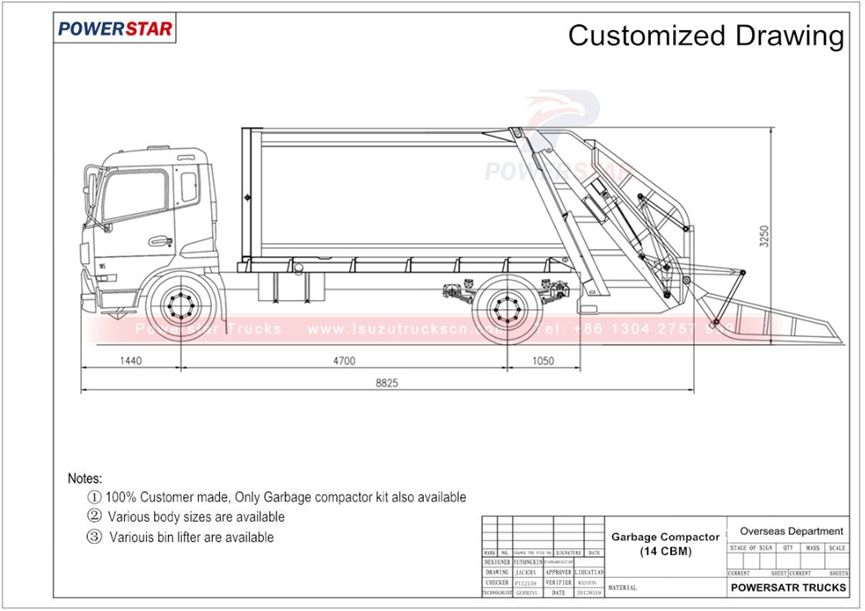

Overall dimensions | 8825X2500X3250mm | Gross weight | 16000kg |

Loading capacity | 14m3 | Curb weight | 8200kg |

Chassis parameters | |||

Chassis model | ISUZU FTR | Chassis brand | ISUZU |

Wheel base | 4700mm | Maximum speed | 95km/h |

Cab | Configuration | FTR,a row and a half cab,allowable 3 passengers,with air conditioner, central locking, electric windows, USB audio, cab can be flipped. | |

Color | White,other color is optional | ||

Engine | Model | 4HK1-TC50 | |

Type of fuel | Diesel | ||

Emission | Euro 5,6 | ||

Type | 6 cylinders, in-line, 4-stroke,Exhaust gas turbo, air-to-air inter-cooling ,diesel engine | ||

Rated power | 205hp | ||

Displacement | 5193ml | ||

Manufacturer | Isuzu Engine | ||

Tire | Size | 10.00-20 16PR nylon tire | |

Number | 6+1 nos | ||

Front axle | 6.3 tons | ||

Rear axle | 13.0 tons | ||

Drive form | 4X2 | ||

Suspension | Multi leaf springs | ||

Rated voltage | 24V,DC | ||

Transmissions | Isuzu MLD six speed transmission,6 speed forward 1 reverse. | ||

Steering device | Power assisted steering | ||

Steering wheel | Left hand drive | ||

Selective configuration | Tire :1000R20,1100-20,1100R20 | ||

Refuse compactor structure parameters | |||

Equipment | |||

Structure | Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems | ||

Loading capacity | 14m3 | ||

System of loading | Mechanized, rear loading | ||

Modes of the pressing | Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic | ||

Body | |||

Version | All-metal | ||

Shape | arc-shaped | ||

Sidewalls | Sheet carbon steel (thickness: 4 mm) | ||

Bottom | Sheet carbon steel (thickness: 4 mm) | ||

Roof | Sheet carbon steel (thickness: 4 mm) | ||

Front frame | Sheet carbonaceous steel (thickness: 5 mm) | ||

Rear frame | shaped profile from sheet carbon steel (thickness:5 mm) | ||

Basis | 120X120mm (thickness: 5 mm) | ||

Loading bunker | |||

Loading bunker | All-metal with sidewalls and a loading ladle | ||

Volume | 1.2 m3 | ||

Sidewalls | Sheet carbon steel (thickness: 4 mm) | ||

Ladle floor material | Sheet carbon steel (thickness: 4 mm) | ||

Liquid drain | Drainage channel,sewage tank | ||

Working zone Lighting | 2 lamps | ||

Mechanism of raising | Two hydraulic cylinders | ||

Ensuring tightness | Between the body and lifting back part in the lower part profile acid-proof rubber is used. | ||

Pressing system | |||

Features | Control mode diversification,bidirectional compression | ||

Pressure | 16Mpa | ||

Compaction ratio | ≥1:3.4 | ||

Loading cycle | 15-20 second | ||

Discharging cycle | 10-18 second | ||

pressing mechanism | The giving plate and hinge related pressing plate moving on two directing bars | ||

Pressing mode | Automatic pressing | ||

(1 full cycle and continuous pressing) and controlling of each cycle of pressing separately | |||

Control of pressing | Control from the external panel on the bunker | ||

Lifting rear part | |||

Mechanism of lifting | Two hydraulic cylinders | ||

Function description | Suitable for various rubbish bins | ||

Others | |||

Color and Logo | Optional | ||

Standard configuration | Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control. | ||

Selective configuration | PLC electric automatic control,multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc. | ||

1. We supply various series of Isuzu special vehicles, such as: 100P, 600P, 700P, KV100/600/800, M100/600, FTR, FVR, FVZ, NPR, ELF, VC66 levels, etc. all available.

2. The drive type could be 4x2 , 4x4 , 6x2 , 6x4 , 6x6 , 8x4

3. We can provide LHD (left hand drive) or RHD (right hand drive) vehicles.

4. Be designed according to your requirement .

5. Small order can be accepted.

6. We accept 100% inspection, welcome to our factory at any time.

7. 12 month quality guarantee term.

III. Details of Algeria Isuzu FTR Garbage Compactor Truck

● Algeria Isuzu FTR garbage compactor truck photos for reference

The Algeria Isuzu FTR garbage compactor truck adopts mechanical, electrical and hydraulic linkage control systems, computer control and manual operating systems. It uses devices such as fillers and shovels to pour, crush or flatten garbage, and squeeze the garbage into the compartment. Compaction and shirk. The vehicle hydraulic system uses manual direct operation of the hydraulic multi-way valve. The hydraulic system consists of a fuel tank and filter system, oil pump, multi-way reversing valve, one-way throttle valve, oil cylinder, oil pipe, etc. The power of the system comes from the engine, which is separated through the power take-off, and the power take-off drives the gear pump to work. The gear pump sucks the hydraulic oil through the oil suction filter and supplies oil to the multi-way valve. When the multi-way valve works, the negative pressure plate cylinder, skateboard cylinder, scraper cylinder, lift cylinder or push plate cylinder moves. When the hydraulic cylinder does not work, the hydraulic oil returns directly to the tank through the multi-way valve.

The hydraulic system of the Isuzu FTR garbage compactor truck is the core part of the vehicle's garbage compression function. The hydraulic system realizes the transmission, conversion and control of power through a series of carefully designed hydraulic components and valves, thereby driving the compression mechanism to compress garbage. Main components:

1. Hydraulic pump: The hydraulic pump is the power source of the hydraulic system and is usually driven by the engine. It converts mechanical energy into hydraulic energy, producing high-pressure oil to provide power for the hydraulic system.

2. Hydraulic oil tank: The hydraulic oil tank is used to store hydraulic oil and ensure that the hydraulic system has sufficient oil supply during work. At the same time, the fuel tank also plays a role in dissipating heat and settling impurities.

3. Control valve: Control valve is a very important part of the hydraulic system, including directional control valve, pressure control valve and flow control valve, etc. They are responsible for regulating the flow direction, pressure and flow of hydraulic oil to ensure that the hydraulic system works according to the set requirements.

4. Hydraulic cylinder: The hydraulic cylinder is the actuator of the hydraulic system. It drives the compression mechanism to compress garbage through the reciprocating motion of the piston. The design of the hydraulic cylinder needs to meet the working requirements and strength requirements of the compressed garbage truck.

5. Hydraulic pipeline: Hydraulic pipeline is responsible for connecting hydraulic components such as hydraulic pumps, control valves and hydraulic cylinders to form a complete hydraulic system. Hydraulic lines need to be properly laid out to reduce pressure loss and the possibility of leaks.

Isuzu FTR garbage compactor truck export to Algeria

Isuzu FTR garbage compactor truck export to Algeria

Isuzu 4X2 FTR garbage compactor truck for sale

The working principle of the hydraulic system of the Algeria Isuzu FTR garbage compactor truck is mainly based on hydraulic transmission and control technology. It realizes garbage compression, filling and dumping functions through a series of hydraulic components and actuators. Here is a brief introduction to how its hydraulic system works:

◆ Power source: The power of the hydraulic system mainly comes from the vehicle's engine. The engine outputs part of its power to the hydraulic system through the power take-off to drive the hydraulic pump.

◆ Hydraulic pump and oil tank: The hydraulic pump draws hydraulic oil from the oil tank and delivers it to each hydraulic actuator through the oil pipe. The oil tank not only stores hydraulic oil, but also plays a role in dissipating heat and settling impurities.

◆ Control valve and oil circuit: The hydraulic system controls the flow direction and flow rate of hydraulic oil through control valves and oil circuits. The control valve can control the flow direction and pressure of hydraulic oil according to the driver's operation or the system's preset program, thereby driving different actuators.

◆ Actuator: The actuator of the hydraulic system mainly includes the compression push plate, filling mechanism and dumping mechanism. When the driver operates the corresponding control lever or button, the hydraulic oil flows to the corresponding actuator through the control valve, driving it to complete the corresponding action. For example, the compression push plate can be pushed forward to compress the garbage in the carriage; the filling mechanism can be opened and closed to realize the loading and sealing of garbage; the dumping mechanism can control the inclination angle of the carriage to realize the dumping of garbage.

◆ Pressure regulation and protection: The hydraulic system is equipped with a pressure regulating device and a safety valve to control the pressure of the hydraulic oil and prevent system overload. When the system pressure is too high, the safety valve will automatically open to release part of the pressure and protect the system and vehicle from damage.

Algeria Isuzu 4x2 FTR garbage compactor truck

Algeria Isuzu 4x2 FTR garbage compactor truck

Isuzu 4x2 FTR garbage compactor truck departure in batches

Isuzu 4x2 FTR garbage compactor truck departure in batches

● Algeria Isuzu FTR garbage compactor truck details

● Algeria Isuzu FTR garbage compactor truck departure in batches

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

没有评论:

发表评论